The DEKRA VT1000 refers to a visual testing (VT) procedure or toolset used by DEKRA, a global expert organization specializing in safety, inspection, and certification. The term is commonly associated with high-standard non-destructive testing (NDT), where visual examination is performed to detect surface defects such as cracks, pitting, corrosion, or welding flaws.

VT1000 may represent either a specific internal procedural level within DEKRA’s testing protocols or a product/tool classification for visual inspections.

Why Visual Testing (VT) Matters

Visual Testing is one of the most commonly used non-destructive testing methods. It relies on the trained human eye, sometimes enhanced with tools like borescopes, magnifiers, cameras, or AI-assisted imaging.

In high-risk industries like:

-

Aerospace

-

Oil & Gas

-

Automotive

-

Power Generation

…a surface flaw can mean the difference between safe operation and critical failure. That’s where tools like the DEKRA VT1000 play a crucial role — catching early signs of degradation before they lead to bigger problems.

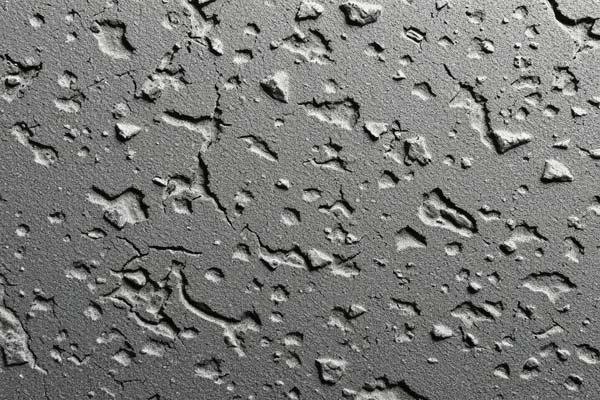

What Can DEKRA VT1000 Detect?

The DEKRA VT1000 system or procedure can identify:

-

Pitting corrosion on metallic surfaces

-

Cracks or fractures in welds and joints

-

Misalignments in fabricated parts

-

Surface wear due to stress or fatigue

-

Manufacturing defects invisible to casual inspection

It supports preventive maintenance, compliance with safety standards, and quality assurance across multiple sectors.

How It Works

VT1000-level inspections involve:

-

Standardized lighting conditions

-

Surface cleaning prior to inspection

-

Use of magnification tools, high-resolution optics, or even remote video systems

-

Visual inspection by certified NDT personnel, often trained to ASNT, ISO, or EN standards

This tier of inspection may also be part of a multi-level quality control process, where VT is the first step before more advanced NDT like ultrasonic or radiographic testing.

DEKRA’s Role in Industrial Safety

As one of the world’s largest inspection and certification companies, DEKRA offers services including:

-

NDT inspections

-

Safety audits

-

Certification of industrial equipment

-

Training and qualification of inspectors

According to Wikipedia’s article on DEKRA, the company operates in over 60 countries and serves a wide range of industries. Its VT1000 protocols reflect its commitment to international testing standards and reliable service.

Final Thoughts

Whether it’s inspecting the welds on a pressure vessel or identifying corrosion on a bridge beam, the DEKRA VT1000 ensures that no detail is missed.

In a world where safety and uptime are everything, precise and systematic visual testing provides peace of mind — and DEKRA’s expertise helps industries stay compliant, efficient, and safe.